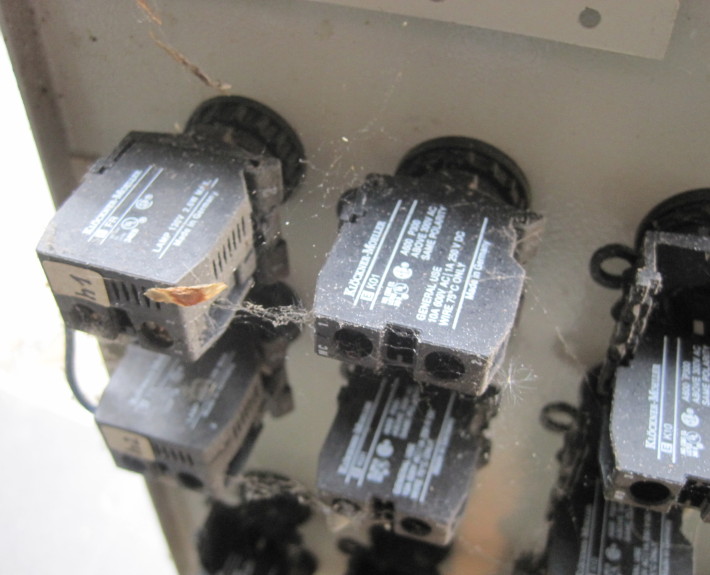

What a beauty! All I knew about this box, is that it was used in a machine at a spice-factory. So maybe it controlled a big chilli or pepper grinding machine back in its younger years.

…but I can´t tell. It must have been a couple of decades ago, as there were entire generations of spiders and insects living happily in there. However it was almost for free with all the crusty switches and buttons included.

…even with free Halloween decoration! awesome!

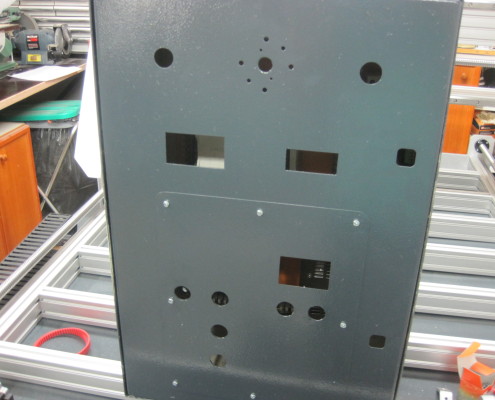

Afer hours of sanding and fighting with the spiders living in it, I managed to paint it in the same colour as the base. I used a 2-component finish, which made the surface very scratch resistant.

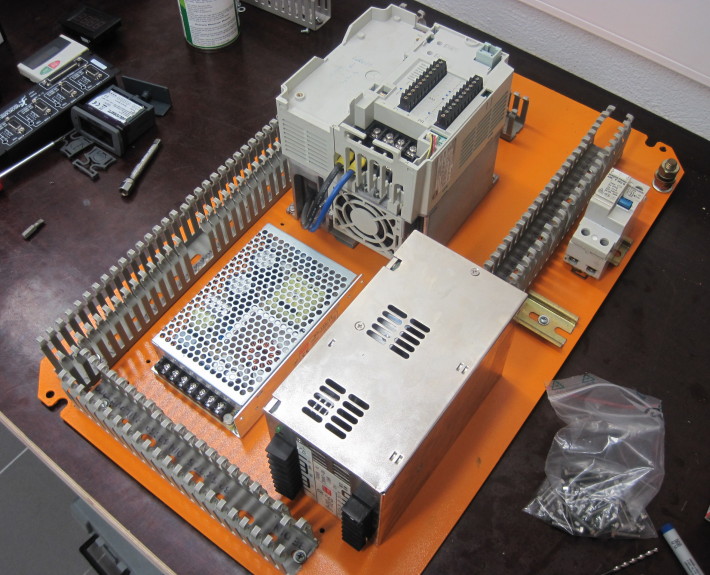

…without all the wiring madness: the power supplies and the VFD strategically placed for best heat transfer. The mounting plate and the cable-tunnels where all in the control box, and just needed some cleaning.

The beast finally turned into a real beauty! The air cooling system consists out of 5 fans inside the box. One big 120mm fan sucks in the cold air at the bottom and directs it to the power supplies which blow the air further to the VFD and the G540 (with two 80mm fans equipped).

In the top of the box is a final 120mm fan which blows the hot air out. I did not even had any temperature problems during hot 40°C periods in summer. However a small temperature display tells me the temperature of the VFD and the water cooling system (spindle).

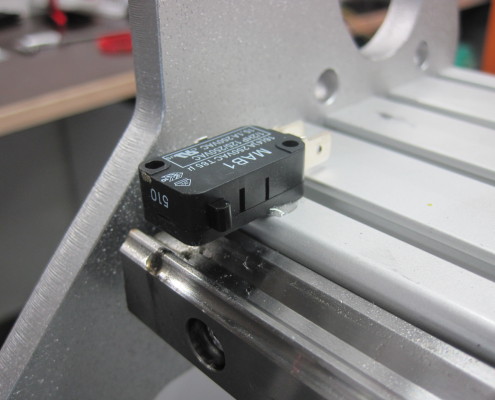

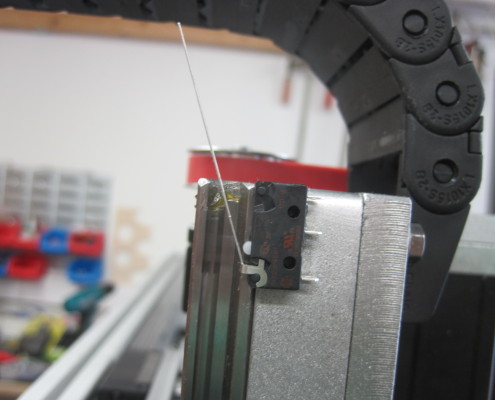

I did not mind where and how I want to place the limit switches during the design stage . However it wasn´t such a nightmare. I used 2c epoxy and glued them down on their spots. If I had a second chance I would recommend to screw the switches down, as they are very important to avoid serious machine damage. The 2c epoxy sticks however quite well on sanded aluminum and steel.